Part I: Selecting the Proper Shielding Materials

At first, we need to introduce a physics concept Skin Depth, before discussing the shielding materials. The Skin Depth δ is defined as the depth below the surface of the conductor at which the current density has fallen to 1/e (about 0.37) of its surface current density[2]. It is visually illustrated in the Figure 1. The Figure 2 shows the Skin Depth due to the circulating eddy currents (arising from a changing H field).

Figure 1: Skin Depth Figure 2: Circulating Eddy Currents

In normal cases the Skin Depth δ is well approximated as:

where

ρ = resistivity of the conductor

ω = angular frequency of current = 2π × frequency

μ = absolute magnetic permeability of the conductor

According to the above description about Skin Depth, we know that the eddy currents will be roughly limited within the Skin Depth when the conductor is placed in the changing field. In other words, if we want to shield a circuit from the changing field with angular frequency ω, then we need to use the conductor thicker than its Skin Depth at angular frequency ω.

Table 1: The Skin Depths of Some Common Metals

| Frequency | Skin depth (mm) Copper | Skin depth (mm) Aluminium | Skin depth (mm) Iron |

|---|---|---|---|

| 60 Hz | 8.4217 | 10.9111 | 0.3257 |

| 10 kHz | 0.6523 | 0.8452 | 0.0252 |

| 100 kHz | 0.2063 | 0.2673 | 0.0080 |

| 1 MHz | 0.0652 | 0.0845 | 0.0025 |

| 10 MHz | 0.0206 | 0.0267 | 7.9788e-04 |

| 100 MHz | 0.0065 | 0.0085 | 2.5231e-04 |

Based on the data in Table 1, we could see the data obey the concept mentioned by Arnold H. Green in his article Shielding Magnetic Fields[1]. Radio frequency (100 kHz and above) shields typically use copper, aluminum, galvanized steel, or conductive rubber, plastic, or paints. These materials work at high frequencies by means of their high conductivity. Unlike magnetic shields (Low Frequency) that use their high permeability to attract magnetic fields, Radio frequency shielding has little or no magnetic permeability.

Part II: Experiment

The shielding performance of Iron and Aluminum was tested by shielding the EMI of the switching power supply as Figure 3. The Magnetic Field Probe was connected to the Channel 1 of the oscilloscope Rigol DS2202 and the distance between the probe and the switching power supply was fixed.

Figure 3: Equipemnts Setting Up

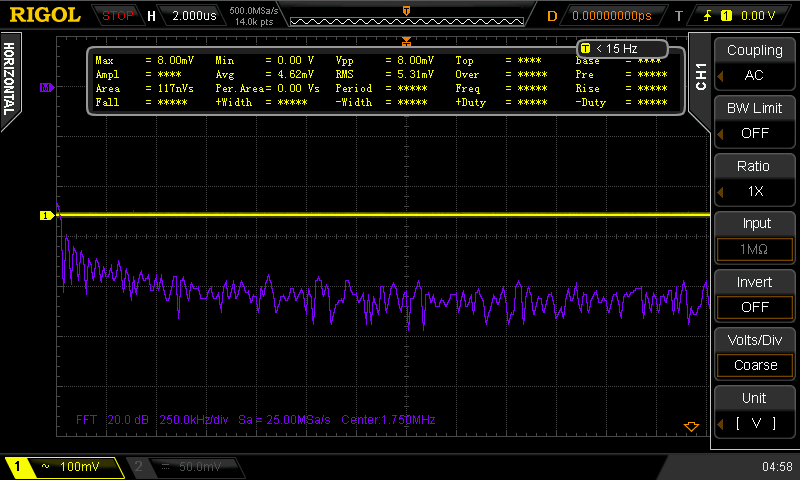

When the power supply did not turn on and there was nothing between the probe and the power supply, the Vpp on the Channel 1 was 8mV.

Figure 4: The measurement when the power supply powering off, nothing between the probe and the power supply

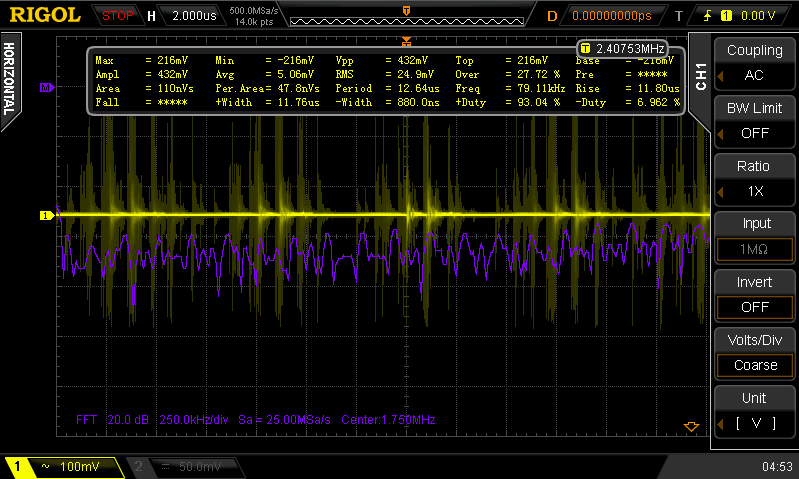

When the power supply turned on and there was nothing between the probe and the power supply, the Vpp on the Channel 1 was 432mV.

Figure 5: The measurement when the power supply turning on, nothing between the probe and the power supply

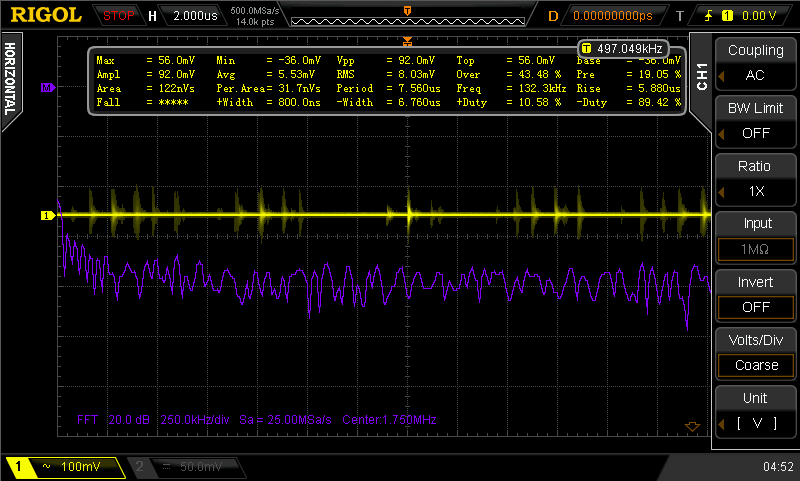

When the power supply turned on and there was a piece of 0.2mm Iron Sheet between the probe and the power supply, the Vpp on the Channel 1 was 92mV.

Figure 6: The measurement when the power supply turning on, a piece of 0.2mm Iron Sheet between the probe and the power supply

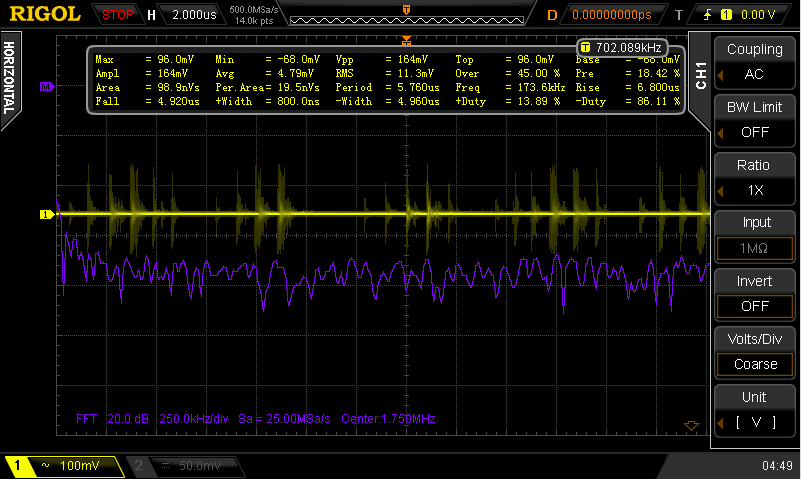

When the power supply turned on and there was a piece of 0.2mm Aluminum Sheet between the probe and the power supply, the Vpp on the Channel 1 was 164mV.

Figure 7: The measurement when the power supply turning on, a piece of 0.2mm Aluminum Sheet between the probe and the power supply

According to the Vpp measurements, the shielding percentage of the 0.2mm Iron Sheet was 78.7% and the shielding percentage of the 0.2mm Aluminum Sheet was 62.0%. We could conclude that Iron has better shielding performance than Aluminum. The experiment results obey the theory explained in the Part I.

Part III: Materials

- Mu-metal (The high permeability of mu-metal provides a low reluctance path for magnetic flux, leading to its major use, in magnetic shields against static or slowly varying magnetic fields.)

Part IV: References

[1] Arnold H. Green. Shielding Magnetic Fields. Retrieved June 20, 2013, from http://www.aip.org/tip/INPHFA/vol-7/iss-5/p24.pdf (Local Mirror)

[2] Skin effect. In Wikipedia. Retrieved June 20, 2013, from http://en.wikipedia.org/wiki/Skin_effect

[3] Neil(Bing) Hao. Measuring EMI with Homemade Magnetic Field Probe. Retrieved June 20, 2013, from https://www.uniteng.com/index.php/2013/05/30/measuring-emi-with-homemade-magnetic-field-probe/